Balzers Vacuum Gas Pressure Gauge TPR

017 KF Pfeiffer

No série

Nickel filament pirani gauge

The Balzers TPR 017 Vacuum Gauge has

been designed for vacuum measurement of gases in the pressure range from

8 × 10-4 to

1000mBar. The gauge can be operated in connection with the

Vacuum TPG 300 total pressure gauge controller.

Basic principle of Pirani gauge

A conducting wire gets heated when electric current flows

through it. The rate at which heat is dissipated from this wire depends on the

conductivity of the surrounding media. The conductivity of the surrounding media

in turn depends on the density of the surrounding

media (that is, lower pressure of the surrounding media, lower will be its

density). If the density of the surrounding media is low, its conductivity also

will be low causing the wire to become hotter for a given current flow, and vice

versa.

|

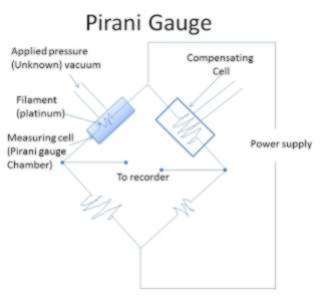

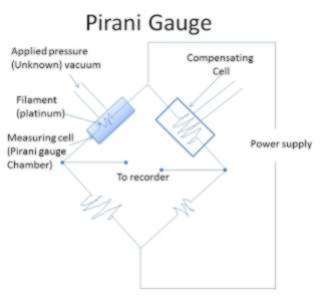

- A pirani gauge

chamber which encloses a platinum filament.

- A compensating

cell to minimize variation caused due to ambient temperature changes.

- The pirani

gauge chamber and the compensating cell is housed on a wheat stone bridge

circuit as shown in diagram.

|

Operation of Pirani gauge

- A constant current

is passed through the filament in the pirani gauge chamber. Due to this

current, the filament gets heated and assumes a resistance which is measured

using the bridge.

- Now the pressure

to be measured (applied pressure) is connected to the pirani gauge chamber.

Due to the applied pressure the density of the surrounding of the pirani gauge

filament changes. Due to this change in density of the surrounding of the

filament its conductivity changes causing the temperature of the filament to

change.

- When the

temperature of the filament changes, the resistance of the filament also

changes.

- Now the change in

resistance of the filament is determined using the bridge.

- This change in

resistance of the pirani gauge filament becomes a measure of the applied

pressure when calibrated.

Advantages of Pirani gauge

- They are rugged and inexpensive

- Give accurate results

- Good response to

pressure changes.

- Relation between

pressure and resistance is linear for the range of use.

- Readings can be

taken from a distance.

Limitations of Pirani gauge

- Pirani gauge must

be checked frequently.

- Pirani gauge must

be calibrated from different gases