Laser Technology

![]()

Laserix

was

specialised in the development and manufacture of lasers for veterinary, medical

and industrial use.

The first generation of industrial lasers machines was developed by Prof. P.

Ravussin in

1966

for the welding of the watch spirals. It was a world first. This first

generation machines was using a ruby

150mm length and of 6,35mm diameter

(YAG crystal was not yet invented). In these early ML01 machines, an analogical

calculator compensates the relatively fast ageing of the “optical pumping” flash

lamp.

|

|

Watch spirals welding: A BissectronÒ

device splits the laser beam in two such a way that the two spots are

weld in the same time.

|

At

this time, a “good” ruby laser was able to pierce a rwo Swiss franc silver coin.

It corresponds to an energy output of about 10 joules. The first ML01 machine

was used to weld

the watch spiral on its coupling ring. Later on, ML01 machines where sold to

Omega Watch Company to weld a watch part simultaneously in 3 points.

One of these watches was worn

by Astronaut Edwin Aldrin in the moon module.

|

|

Arming wheel of the Omega Speedmaster welded simultaneously in three

points (inside the black circles) |

The ultimate development of the ruby lasers ML01 machines was the construction

of huge double machines delivered to a Siemens factory. They served to weld the

spring and the contacts of miniature relays. Each

has a “MultisectronÒ”:

this patented device divides the laser beam before the optic and therefore welds

several points at a time.

Prof. P. Ravussin was successful where the

hughe

Siemens laser laboratory has failed.

The double ML01 laser machines under construction

A new

synthetic laser crystal Nd:YAG was invented in 1964. It

is today the most widely used active laser medium in

solid-state lasers. Laser made with Nd:YAG have much

better performance then the ruby lasers. However the maximum energy for a given

crystal size is much less.

Ruby stone is widely use in high quality mechanical watches and jewel bearing

instruments. Mechanical drilling has been replaced in the 70th with

laser drilling. Laser drilling of sapphire or ruby is a very complex phenomenon

that is not easy to master. Our ML05 laser drilling machines have been optimised

over decades of industrial production.

|

|

Ruby stones in a mechanical watch |

As

soon as the Nd:YAG crystal becomes available in the early seventeen,

Prof.

P. Ravussin started to develop watch stones drilling machines. It is a difficult

task because the laser energy shall be very stable, the laser beam shall be

perfectly round, and the machine shall be mechanically perfectly stable over

millions of shots.

|

|

Watch

stone undrilled

|

Hard stones drilling is made with specially designed laser machines. The laserix

ML01 to ML06 machines have mass produced

billions of stones of various diameter and thickness.

Basically the process is as following:

|

|

|

The jewel bearing drilling (sapphire, ruby, etc.) is mainly a percussion

drilling. A succession of laser shots is needed to pierce the stone. The number

of shots and the total energy of each shot

shall

be programmed according to the thickness of the stone and the diameter of the

hole to be pierced. Each shot is composed of hundreds of laser spikes of very

high peak power and very short duration separated by dead time. It is this

succession of spikes that helps to drill holes much longer that the diameter.

The ejected material is volatilized.

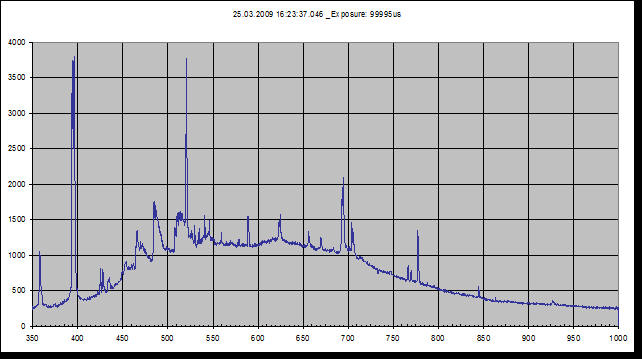

The spectrum of the drilling flame shows that the temperature of the plasma

reaches 5500K. The emission line of Cr3+ in the ruby

stone

at 694,3nm can be easily recognized

in the following spectrum

as well as other Cr

Actually the peak power needed to drill can only be reached with flash lamp

laser pumping.

The ML05

laser drilling machines are able to pierce holes of a diameter ranging from a

few micron to 2/10 of mm ore more on sapphire and ruby. The change from one type

of stone to another one is made rapidly. For larger diameter hole trepanning

machining shall be used: a serial of small holes are pierced over the

circumference. Narrow holes can be pierced to a length of a few millimetres.

The ML05

watch stones drilling machine keeps the vertical configuration of the earlier

machines that minimized the required floor space to approx. 700mm x 600mm only.

The height of the machine is 2600mm.

Watch stones drilling workshop |

|

Controls

The ML05 hard stone laser drilling machine is controlled by means of a computer

installed in the base of the machine. The hard disk is a solid state drive (no

moving part) that has

100+ Year Life Expectancy (MTBF). The motherboard is an “Ultra

Durable 2” designed model with top quality long life components.

The control software is the bug free,

goof protected

Ml05 software. The operator can configure the machine for different type

of stones (number of shots, energy of each shot). Each configuration can be

saved and retrieved when the same kind of drilling shall be realised.